Stopped-Flow Instrument

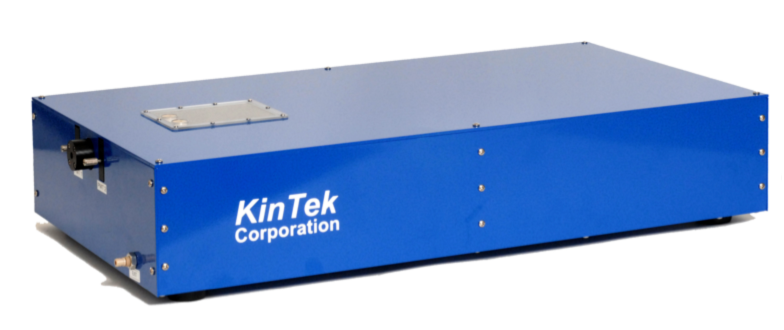

AutoSF-120

The AutoSF-120 enables the exciting era of automated high throughput stopped flow with the optional robot! Without the robot, the AutoSF-120 offers quick and efficient loading of small sample volumes.

KinTek has always been a leader in building stopped-flow instruments that conserve precious samples. The all new AutoSF-120 sets a new standard for sample economy, requiring only 120 microliters of a sample to flush, load and collect data while giving with 3-4 replicate measurements. The flushing and sample loading are all done automatically! Simply pipette 120 microliters of solution into each sample cup and click "Load".

In the process of designing this new state-of-the-art instrument, we also added new noise reduction electronic circuits to improve signal/noise twofold and achieved a submillisecond dead time. In addition, we completely re-wrote the system software for data collection and analysis to give unparalleled ease of use and power.

The KinTek AutoSF is by far the best stopped-flow instrument ever built, giving you more high-quality data while consuming less sample and less time. If you have been using an antiquated and awkward system using air cylinders and stop syringes, you will be blown away by the ease of use and data quality of a KinTek stopped-flow.

An optional robotic autosampler increases throughput even more to afford unattended stopped-flow measurements of hundreds of samples per day.

Features

Small sample volume: 120 µL is sufficient to flush and load a new sample and get 3-4 reproducible shots. All other instruments require 3-5 times as much sample.

Automated computer-controlled load/flush/fire cycle — simply pipette as little as 120 µL into each sample cup and click "Load New".

Twofold improvement in signal/noise with new noise reduction circuits

Compact footprint: instrument and electronics combined (14 × 26.5 × 4.5 inches)

Computer optimized optical path with lower noise and background fluorescence

Optional Robot Affords High Throughput Screening

The AutoSF-120 can be optionally supplied with a robot that automates the loading of up to 32 pairs of samples. Stopped-flow data are collected, and the results are tabulated for easy review. This unique functionality allows unattended high-throughput screening while still delivering the rich information content derived from transient-state kinetic analyzes.

Automatic Sample Loading

Even without the robot, the KinTek AutoSF-120 affords automatic sample loading and syringe flushing between samples while consuming the minimal volume of sample. The AutoSF-120 requires 3- to 5-fold less sample compared to other stopped-flow instruments!

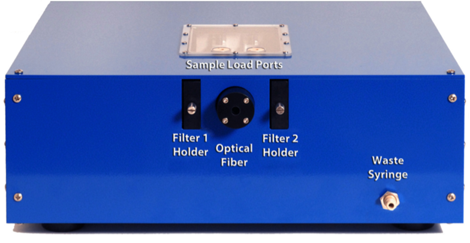

An optical fiber from the light source plugs into the Optical Fiber holder. Two sliders hold filters for each PMT (photomultiplier tube). Pull out the slider and insert the appropriate 25.4 mm diameter filter. Attached a syringe to the EXlT line to collect waste solution.

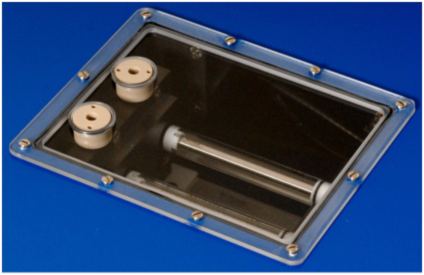

Sample Load Ports

There are three different sample load ports that can be installed to adapt to your needs. Microvolume adapters (standard) contain a conical sample holder into which small volumes (100 to 350 µL) can be pipetted, either manually or robotically. Syringe adapters allow a syringe (without a leur lock) to be inserted into the port. Tubing adapters allow the solution to be fed into the instrument through a 1/16" diameter tubing.

SYRINGE FLUSH/LOAD CONTROL

KinTek stopped-flow system software allows the user to Load Samples and Flush Syringes and to control the volumes taken up during each action.

Text entries under Syringe Volume Controls define the volumes for loading and flushing each syringe. Start by entering a value of 300 next to the Flush Syringes button, then pipette at least 300 µL of the buffer into each load port, and then press Flush Syringes. The instrument will automatically load and expel the set volume. Repeat as needed. To load the syringes with 120 µL of solution, pipette 120 µL into each load port, and then press "Load Sample" as described below. Recommended minimal load volume is 120 µL while the recommended flush volume is 300 µL.

Summary

The KinTek AutoSF-120 represents a significant advancement in transient-state stopped-flow kinetics.

Contact our sales office to get more information on this exciting new advance in stopped-flow instrumentation. The AutoSF stands out in a class by itself. No other instrument offers such sample economy, ease of use and power to collect the most precise data to answer important scientific questions.

The KinTek SF software also allows for easy export of data for analysis using KinTek Global Kinetic Explorer, the most advanced and powerful data fitting package available, enabling you to fit data to models based upon experimental designs, not to equations.